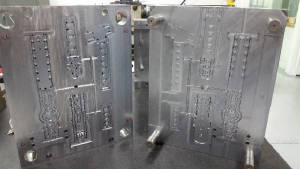

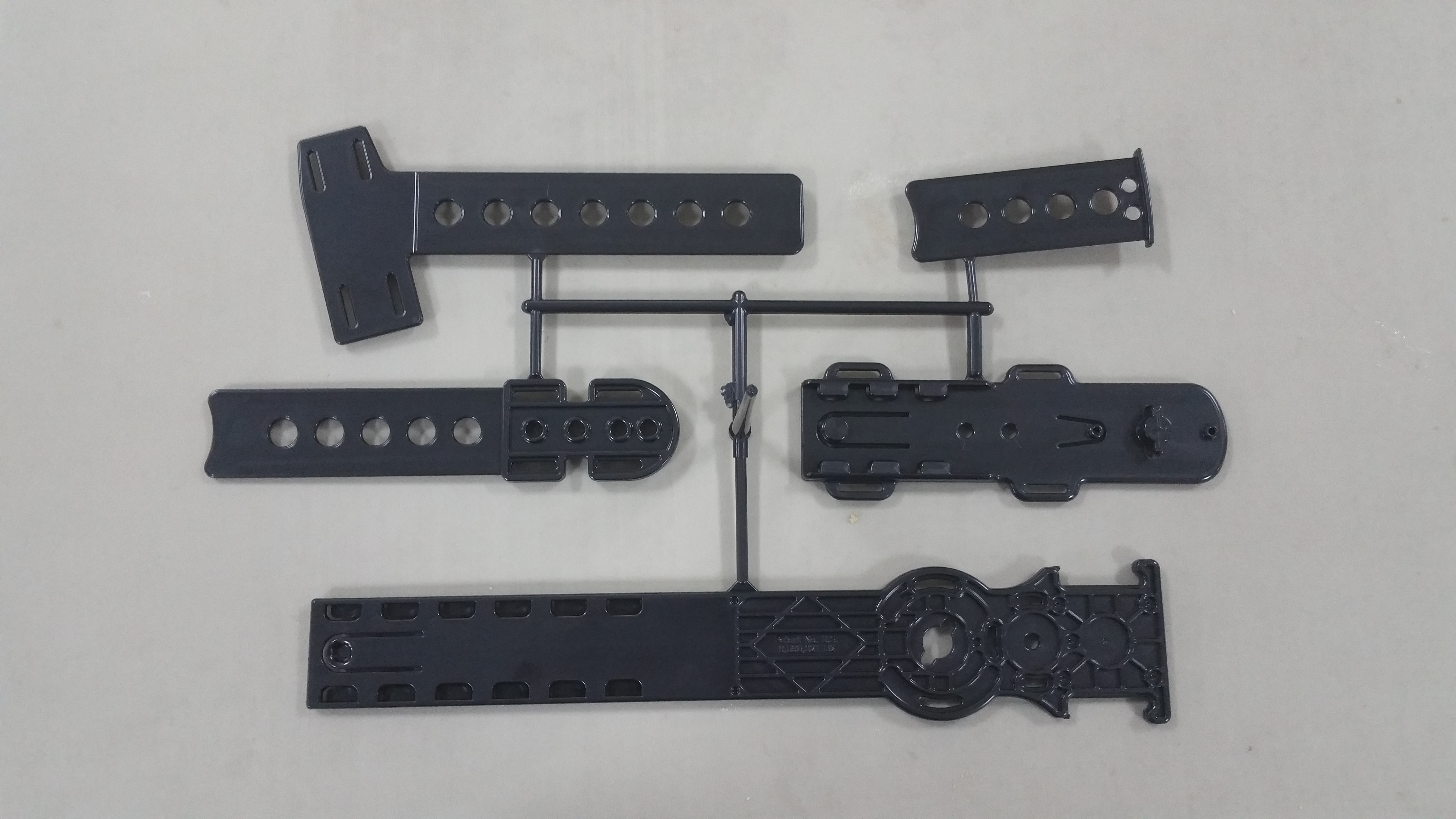

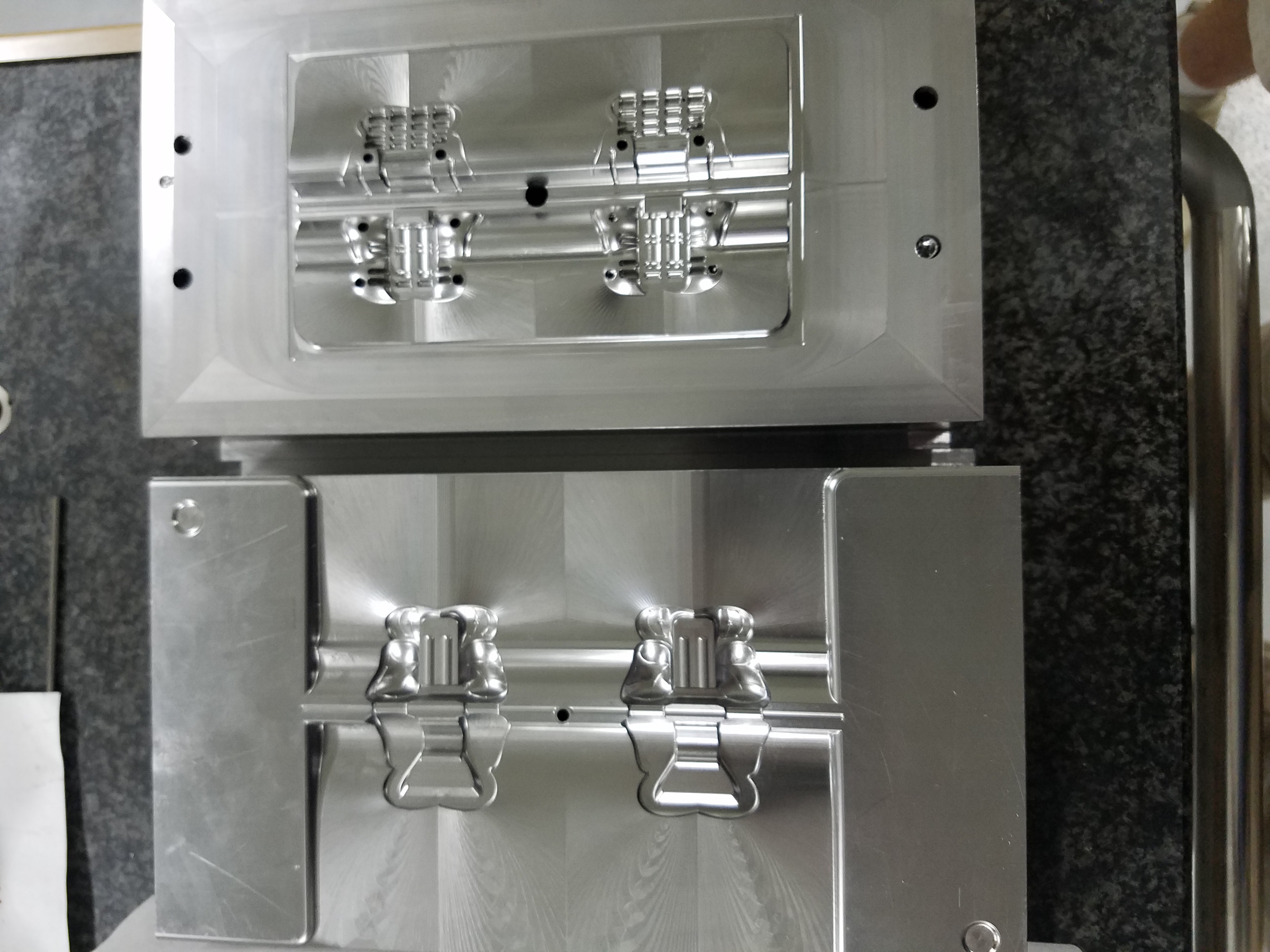

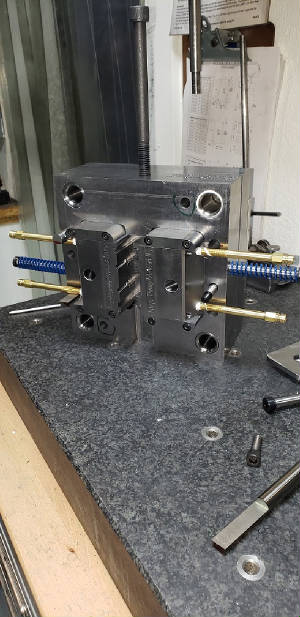

TSR Molds Inc.Plastic injection Molding & Tooling

Projects Past and Recent

|

|

|

Here are a few past projects check in a to our new update coming TSR Molds Inc. 671

Washburn Rd. Melbourne Fl. 32934 321-305-3526

|

Enter supporting content here